Data Distillations

Data Distillations

Data Distillations utilizes Rock River Laboratory’s vast database of feedstuff information from across the United States, along with our expert team, to share important insights, quarterly.

Keeping the agriculture industry in front of challenges and opportunities with available feedstuffs trends is pertinent to farm success. With this in mind, we share relevant data, distilled into graphics and highlights, along with what our team members are gleaning. Prepare for and remedy the peaks and valleys of feedstuff components with the help of another set of eyes.

Sign up to receive alerts when new nutrition Data Distillations are available each quarter by completing the thirty-second form at the bottom of this page or click the link here.

November 17th, 2025

Author: Katie Raver

The not-so-explicit F word

While it’s tempting to paint fat in a negative light, much like in human nutrition, our view on fats in dairy nutrition is always evolving. How many of us remember when whole milk was portrayed to have negative health impacts? Now, research shows that dairy fat can improve heart health. Not long ago, we would broadly suggest dietary fat levels for dairy cattle should not exceed 5.5% in order to maintain efficient rumen function. However, technology such as rumen-protected fats and crop genetics have likewise updated these guidelines. Alongside cattle genetic improvements, these technologies have improved our ability to push milk fat production to the next level, with many Holstein herds producing over 4 percent fat on average and over 7 pounds of total components.

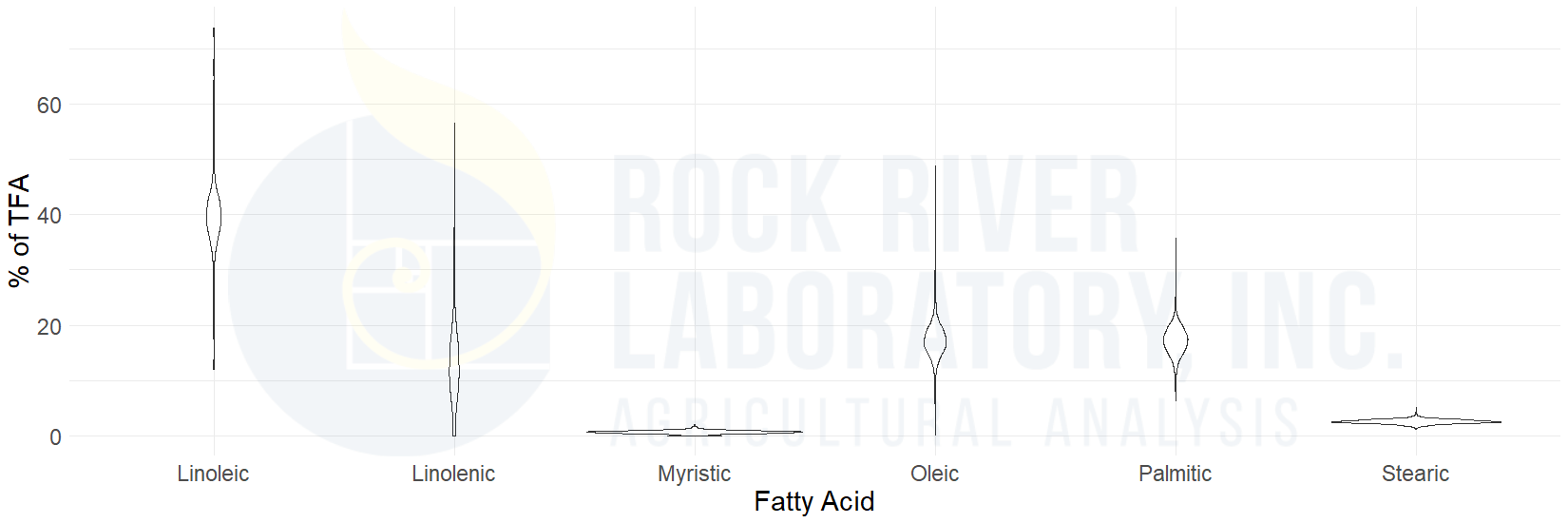

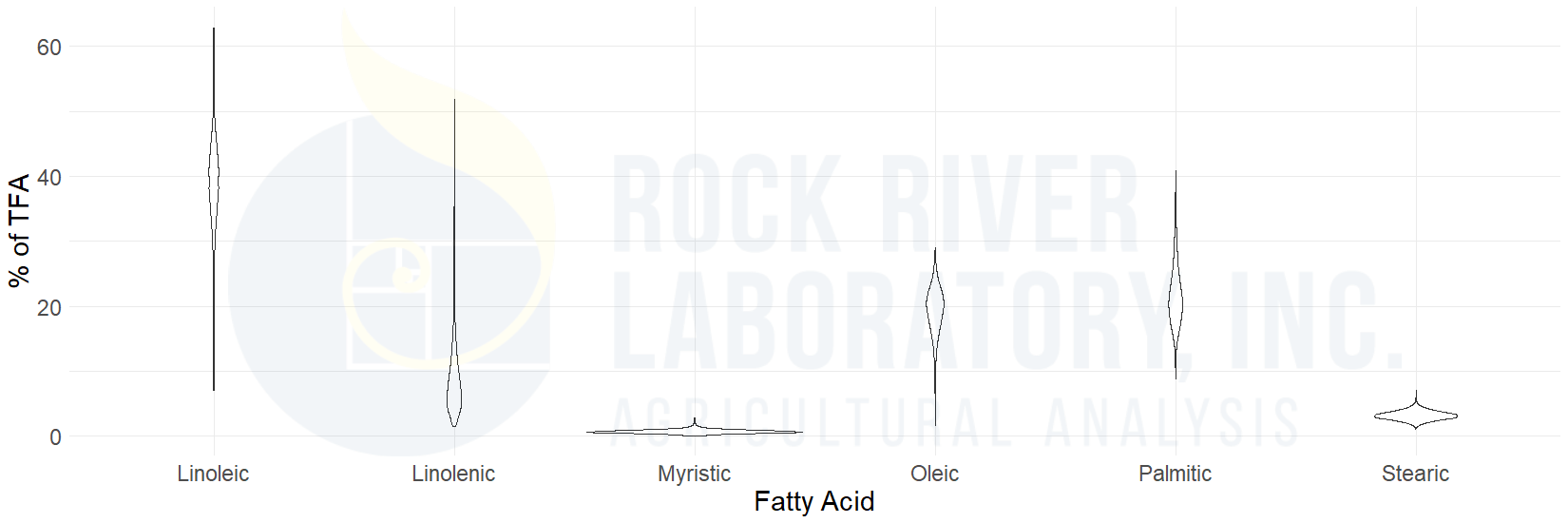

We still need to keep a close eye on which fats we are using to achieve these goals. Too many unsaturated fatty acids can decrease biohydrogenation in the rumen and lead to milk fat depression (MFD). When we look at the average fatty acid content of TMR from 2018 to 2025 we see a large range in linoleic, linolenic, oleic, and palmitic acid content. Comparing these date ranges, linoleic and linolenic content has shifted down while others like oleic and palmitic have increased in their place. This could be in part due to the greater implementation of feeds like high oleic soybeans and increased use of protected fatty acids.

Figure 1: Fatty acid content range in TMR samples from 2018 (Figure 1) and 2025 (Figure 2), respectively

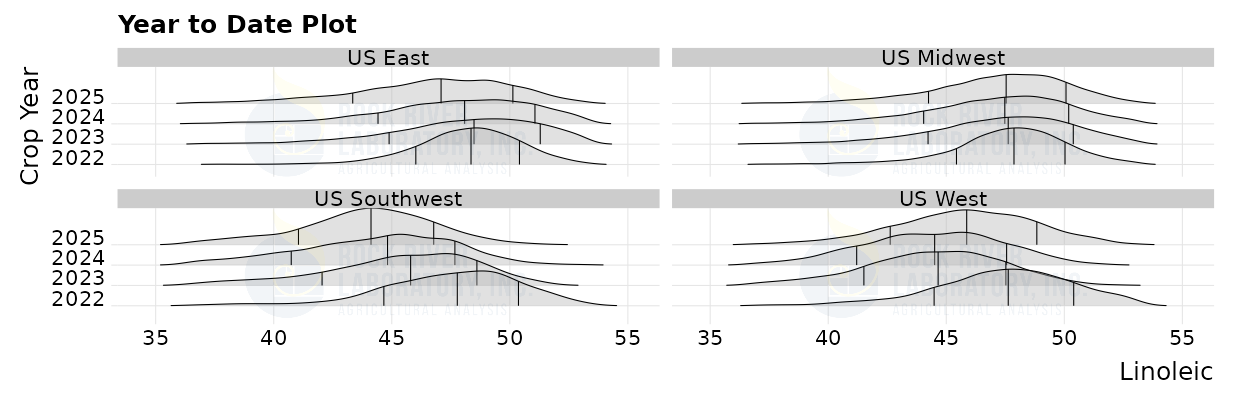

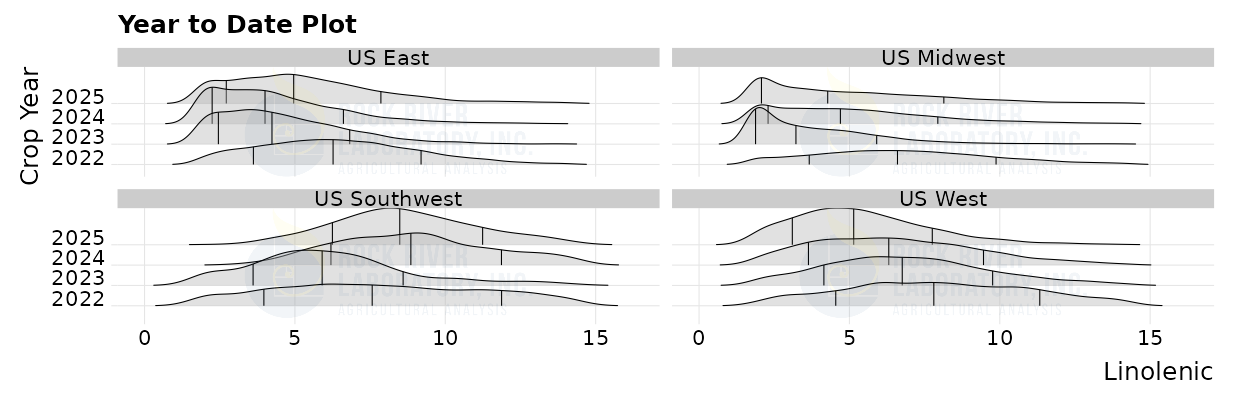

Due to overall low fat content in corn silage, we may be tempted to overlook this as a culprit for MFD. However, the fat content is mostly unsaturated fatty acids and, at high feeding rates, corn silage can add a significant amount of these undesirable fats to the ration. Research has shown that fatty acid content of silage can widely vary, based on growing conditions and management practices. Figure 3 below shows the range in linoleic and linolenic, two major culprits for MFD observed in corn silage.

Figure 3: Distribution of Linoleic Acid percent of TFA in corn silage across different US regions

Figure 4: Distribution of Linolenic Acid percent of TFA in corn silage across different US regions

While this is just one example, any feed contributing a significant amount of total fatty acids can be a culprit for lower-than-desired milk fat production.

August 15th, 2025

Author: Cliff Ocker

Using KPS to improve starch digestibility in corn silage

As corn silage season is closing in on us, hopefully we are helping producers review and monitor tips for a successful harvest season. Corn silage is unique in that we have one opportunity to get it right yet it is often the staple in diets for its energy contribution. Over the years we have found that reducing the particle size of the kernel is one way to improve starch digestibility and gain more energy from our corn silage crop. Much effort has been made to break the kernel down to a less than a 4.75mm size - helping maximize the starch utilization of this feedstuff.

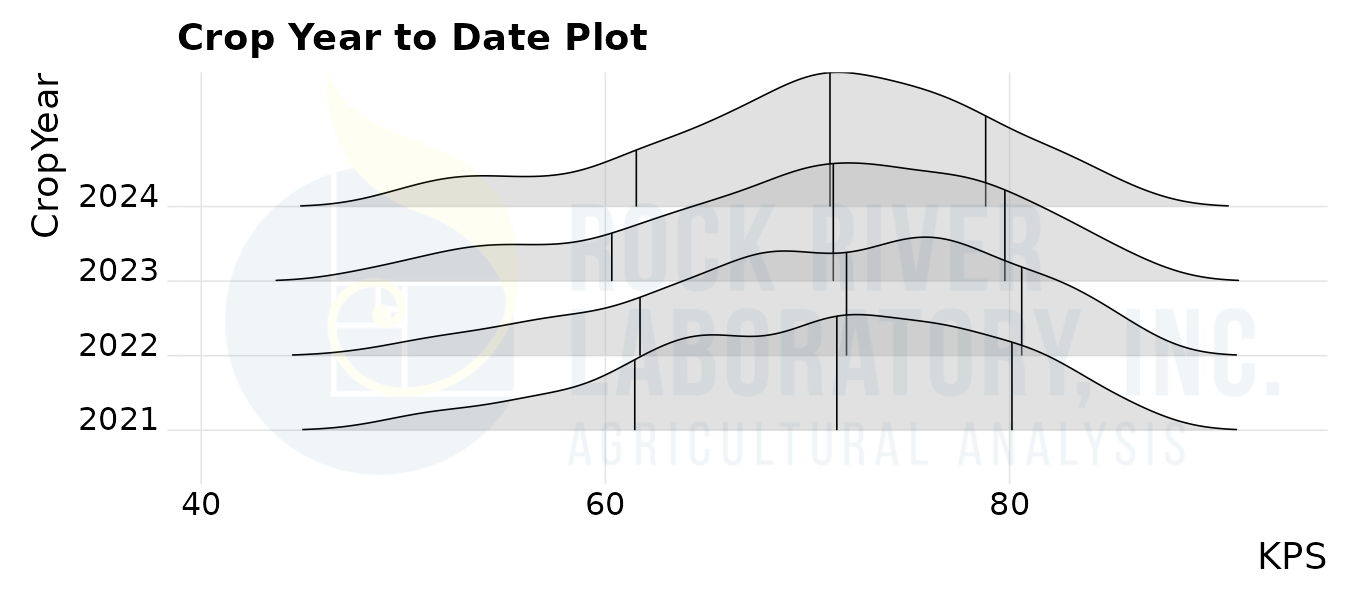

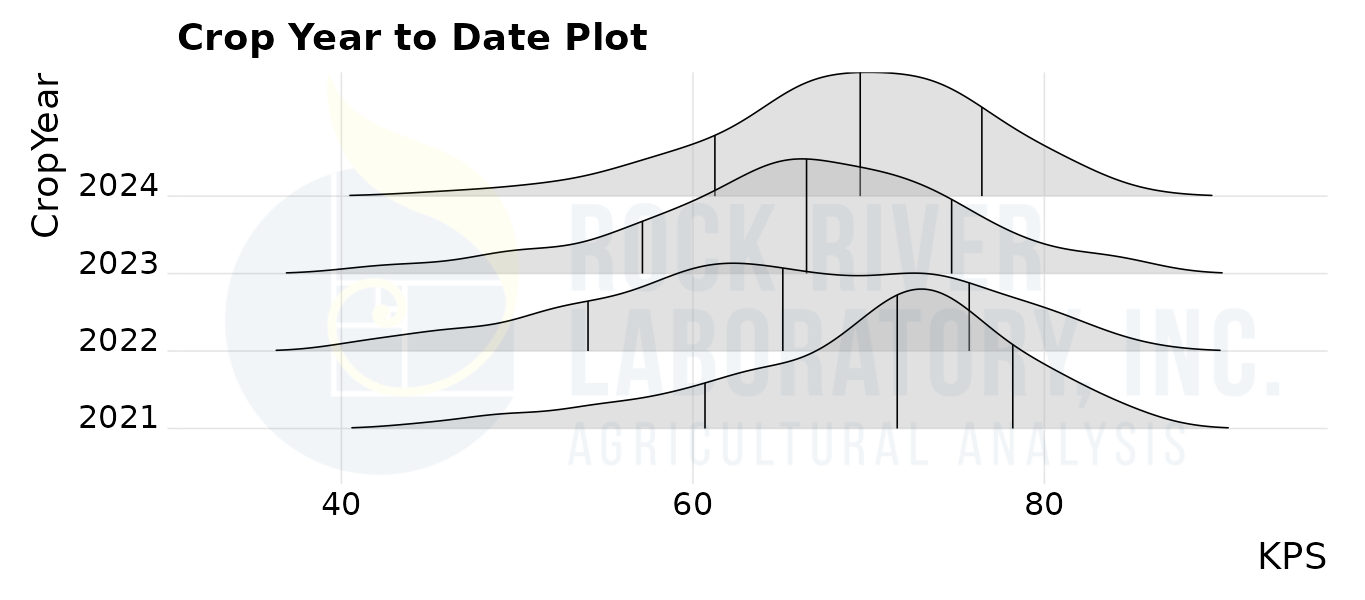

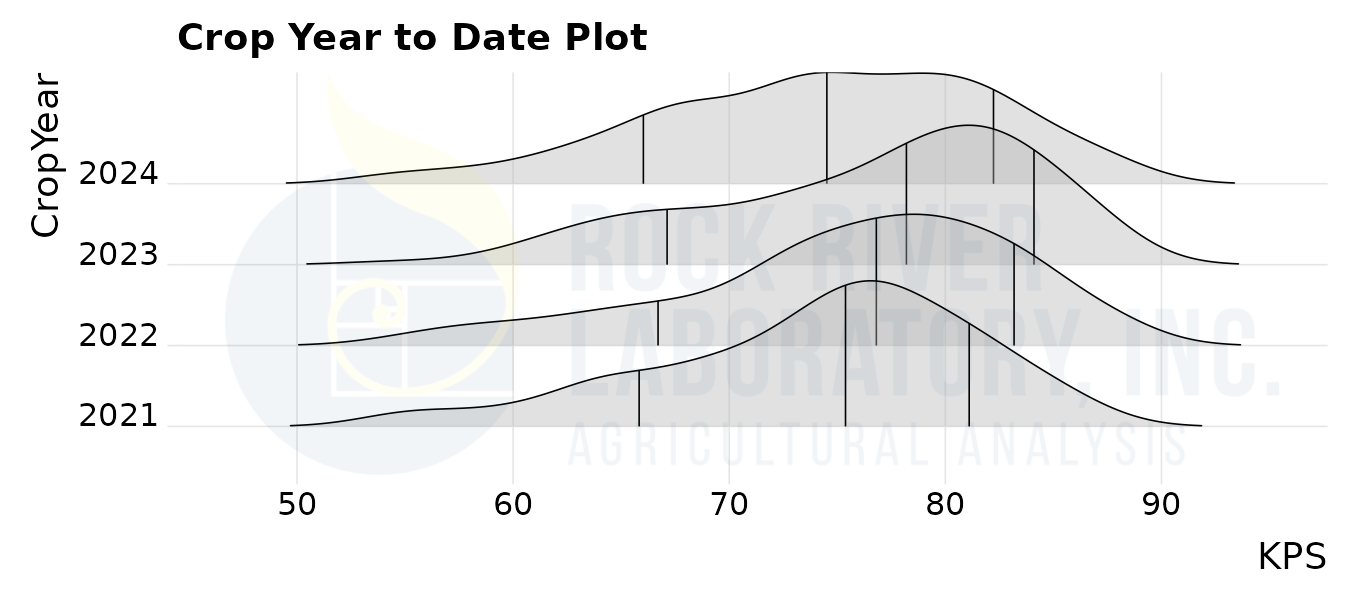

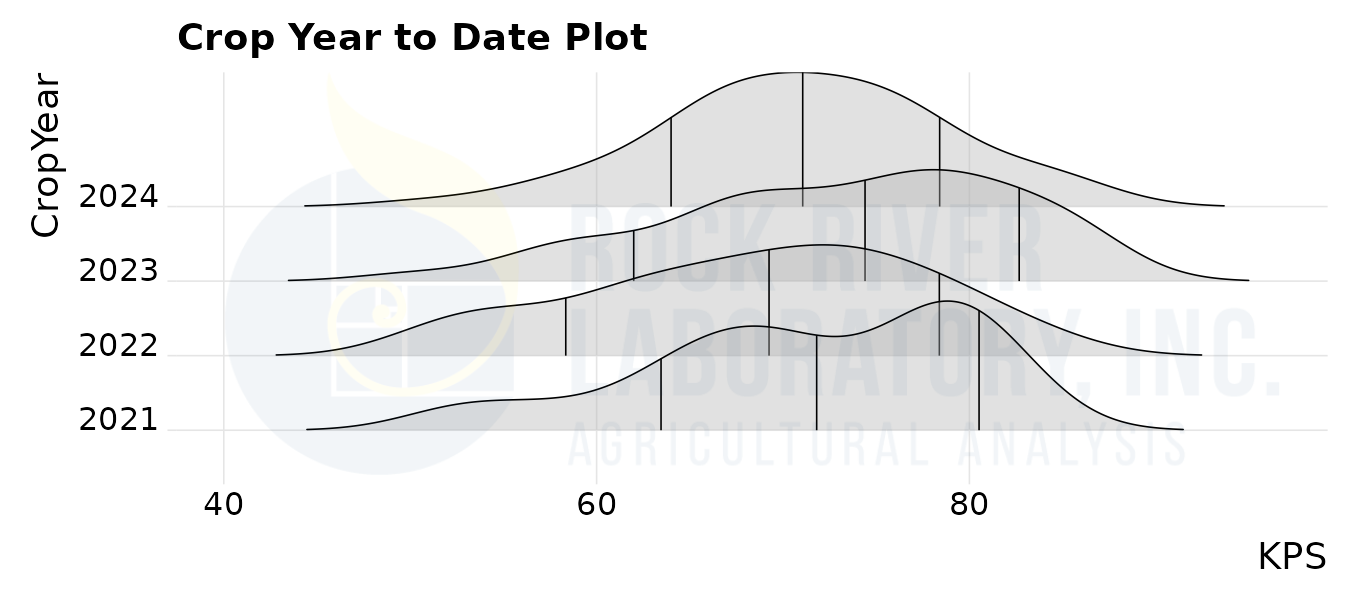

A few years back, we suggested 75% as the goal for KPS as that is what the top 15% of our clients were able to achieve. Checking in on our progress, note Figures 1-4 below, which show our last four crop seasons by region for KPS of corn silage. Over the past four years, the eastern US is averaging 67.6, the Midwestern US is averaging 70.9, the western US is coming in at 74.4 on average, and the southwestern US is averaging 70.8. With these averages, there is still plenty of samples testing below 75% - leaving opportunity to improve, as the lower 15% are averaging about 61%, collectively.

Figure 1: Corn Silage KPS - East

Figure 2: Corn Silage KPS - Midwest

Figure 3: Corn Silage KPS - West

Figure 4: Corn Silage KPS – Southwest

We can now predict KPS by NIR at Rock River Laboratory. While we don’t provide a value (by NIR), we will provide you with a distinction of whether the sample is above or below 70%. This can offer a quick reference as to any necessary adjustments needed during harvest.

Reducing the particle size of the kernel creates increased surface area, which can improve starch digestibility at both the fermentation process and feedout. When feeding corn silage as an energy source, obviously, we want the cattle to be able to digest as much of the starch as possible. One way to monitor this is to check fecal matter for starch, which we conduct via NIR as well. Studies show the correlation of KPS to fecal starch, which trends fairly well in demonstrating that KPS needs to be over 70%.

How much does KPS improve starch digestibility? The Rock River Laboratory database showcases starch digestibility improving nicely as KPS increases, as seen in Figure 5. Note the nearly 8-point improvement in starch digestibility when comparing the samples on the left, at less than 65% KPS, to the samples that are over 70% (third bubble). Getting KPS right might cost a bit more in time and fuel, but the cows will thank you later in performance when these goals are met.

Figure 5: Starch Digestibility based on KPS Score

If you would like a quick determination of KPS, just request our Comprehensive Nutrition Analysis (CNA) for your corn silage to get the ‘above or below’ 70%. We would be glad to run the actual KPS on any sample as well to help make sure goals are met.

May 5, 2025

Author: Cliff Ocker

Who's getting fat when you feed fat?

Heading into warmer temperatures, we often begin considering additional fats in the diet for several reasons. Perhaps it’s driven by body condition and breeding, or performance and butterfat. Regardless of the reason, many factors compose any decision toward additional fat in the diet. Pricing certainly has come into play as a plethora of fat sources add significant cost to the diet. Availability can be another factor. But, have we considered the digestibility of the fat we are feeding?

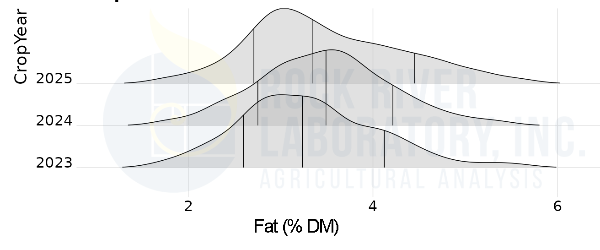

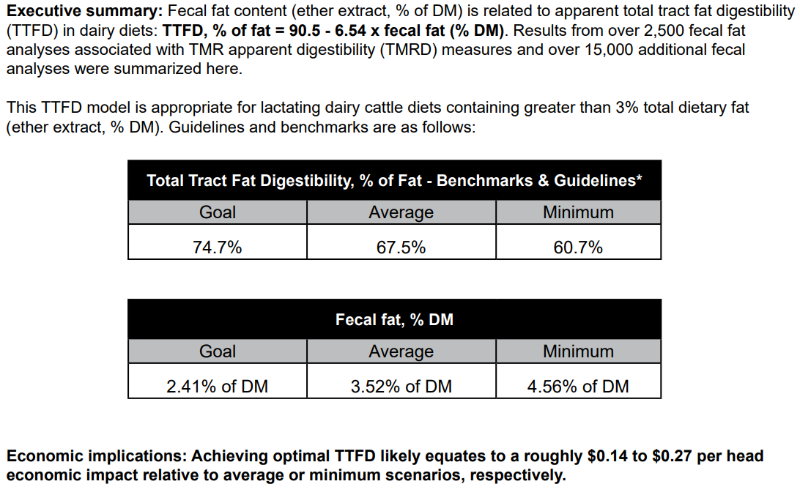

For a number of years, Rock River Laboratory has been testing fat levels in fecal material. We typically use wet chemistry and marry those results with an associated TMR sample to then calculate the amount of fat digested - as we do for Crude Protein (CP), Neutral Detergent Fiber (NDF), and Starch. Recently we have added a Near Infrared (NIR) package to test fecal samples for fat and starch, offering an opportunity to calculate Total Tract Starch Digestibility (TTSD) as well as a Total Tract Fat Digestibility (TTFD).

Figure 1: Fat Level in Fecal Samples by Year

What could this tell us and how beneficial could it be? As we look to our data, Figure 1 above shows the distribution of fecal fat that we have found over the last 2.5 years. While the amount seems small, averaging about 3.5%, remember to consider the cost of what may be complete bypass. When we move this to a TTFD value, I find that many nutritionists are surprised to hear that the average TTFD is 68%, with a range of about 61% to 75%.

Economically, using some typical diets and costs, we feel the benefit of moving from the low end of the range (61%) to average (68%), could improve profitability by $.14/cow/day. If we were to move from the low end (61%) to the high end of the range (75%), this number is more like $.27/cow/day. This information is highlighted in the guidelines below:

Rock River Laboratory Total Tract Fat Digestibility (TTFD) Benchmarks

We’re often looking for the next bump in profitability - this could be a unique tool to help as we consider fat sources in the diet. When pulling a fecal sample, be sure to capture material from 8 to 12 animals, preferably less than 150 Days In Milk (DIM) is best as these are the ‘workhorses’ on the farm. Grab as fresh a sample as possible and chill quickly, or even freeze, depending on how fast you can transport to the lab. Especially with summer’s heat and moisture, the starch in particular will continue to break down. Our Comprehensive Fecal package will provide both the TTSD and TTFD.

March 24, 2025

Author: Katie Raver, MS

2024 - what lies beneath (the plastic)

By: Katie Raver, MS

For many, the 2024 year crop looks to offer several advantages over the 2023 iteration. As we begin to feed out this new crop, reviewing the database can help better prepare us for what this new crop has in store from a nutrient perspective.

Starch

Digestible starch is a major energy source in corn silage, accounting for roughly 55 percent of the Total Digestible Nutrients (TDN) supplied by corn silage. Starch content is influenced by a multitude of factors, however environmental conditions, particularly rainfall, are especially impactful for starch accumulation. Drought in the Southwest led to lower starch content on average compared to other regions where a slight increase in starch content was observed.

Figure 1: Starch content in corn silage across different US regions (2022-2024)

When looking at starch digestibility pre-ensiling, most regions seem to show improvement, compared to 2023. These factors combined lead to higher likely Rumen Degradable Starch (RDS) for most US regions when compared to 2023. However, exact environmental and management conditions may lead to slightly different outcomes for specific locations.

Fiber

Fiber digestibility is another key quality parameter to evaluate when understanding the corn silage crop potential, making up roughly 18 percent of the TDN contribution. While the Midwest is showing slightly lower than average Total Tract Fiber Digestibility (TTNDFD), the eastern and western US saw sizable jumps in this metric. Southwestern corn silage exhibited TTNDFD similar to previous years. Similar trends were noted across NDFD30 values.

Figure 2: TTTNDFD content in corn silage across different US regions (2022-2024)

Net Impact

So when we combine all factors, what does our 2024 prognosis look like? With so many nutrients moving in different directions, what’s the best way to look at net changes? Tools like the Modified Beef TDN value created by Dahlke and Goeser, and the new Milk 2024 are perfect for just that! When looking at beef per ton, we see that the eastern, midwestern, and western US all saw improvements in both milk per ton and beef per ton estimates, while the southwestern US saw slight decreases in beef per ton potential due to lower starch content and lower fiber digestibility previously. Variability across these values remained quite large in all geographic areas, highlighting the importance that individual geographic locations and management plays in defining an individual crop’s potential.

Fig 3: Milk 2024 estimates for corn silage across different US regions (2022-2024)

Fig 4: Beef per ton estimates for corn silage across different US regions (2022-2024)

Looking forward

While reviewing regional data trends can provide some guidance and prepare us for what to expect from a past crop year, monitoring corn silage as it’s harvested can also help prepare for the future of the crop. Robust harvest sampling programs put producers in a more proactive position to make decisions for future years rather than relying on general trends.