By: Katie Raver, Animal Nutrition Technical Services Director

Tip #1: Corn silage will be ready around 45 days after tassel (or a few days after at silking) according to the long-standing rule of thumb. However, the number of days until the ideal dry matter (DM) can range widely, depending on rainfall and accumulated growing degree days. One study from Cornell University found that actual days from silking to 68% moisture varied from 31-45.

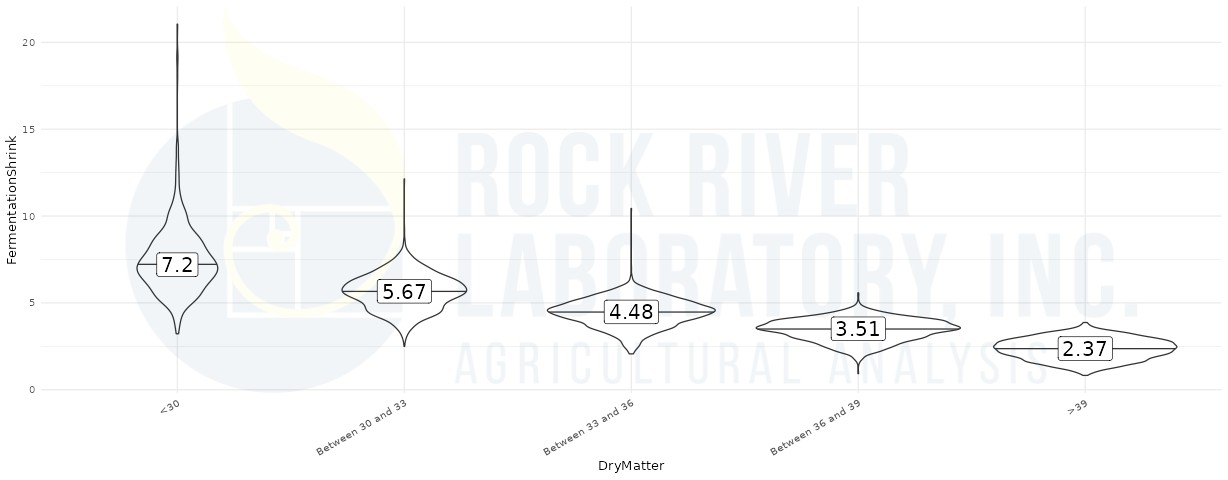

Proper harvest moisture helps ensure the crop will ensile and pack properly. Figure 1 below shows how less-than-ideal DM in corn silage can lead to increased risk for higher fermentation shrink. If DM is too high and the crop is too mature, fiber quality can be compromised. While it may be tempting to visually assess dry matter, appearance can often be deceiving. Crops with high starch content will often look greener while maintaining at or around ideal DM, due to the grain’s higher DM content. On the other hand, drought-stressed corn that lacks grain may take longer to reach the ideal DM. The best way to ensure the crop is harvested at the proper moisture is to directly measure - and a representative sample is critical.

Figure 1: Fermentation Shrink

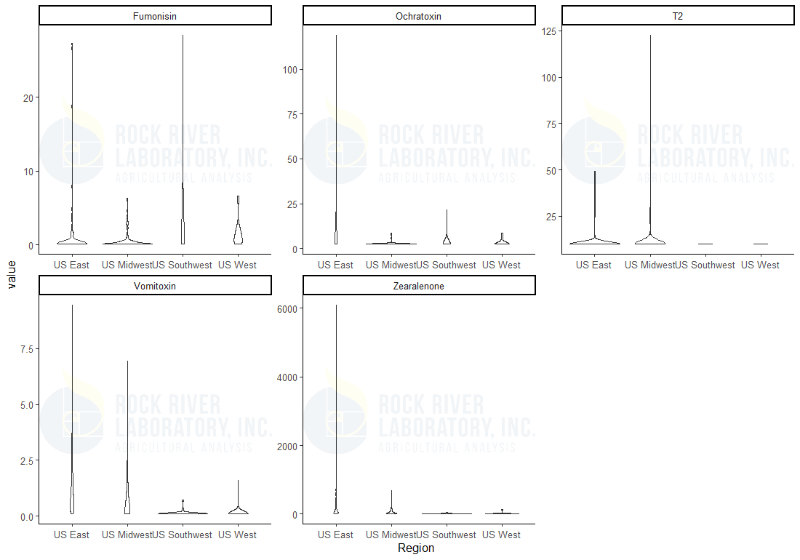

Tip #2: Fungal pathogens can pose a serious problem for both crop quality and animal health. Although most of our US crops are past the point of ideal fungicide application for disease control, proper harvest timing and ensiling can help decrease the risk of further mycotoxin production. If fungal disease is suspected, mycotoxin testing should be considered to ensure feed is safe, and diluted to the proper amount (where toxins are present). Dry matter can decrease quickly in plants with fungal disease, so monitor these fields closely as they can be harvested before they get too dry. Check out what the 2024 corn silage crop looked like:

Fungal diseases are pesky pathogens that rob yield and feed quality, and some species also produce mycotoxins - which can have serious impacts on animals. Some fungal species, such as aflatoxin, are prominent in hot dry conditions. Others, such as fusarium spp., thrive in cool damp conditions. While some may present as ear rots, others can impact both ears and stalks. Regardless of the location of infestation, mycotoxins can still be produced. In poor ensiling conditions, some of these will even continue to grow and produce mycotoxins in the silage pile, bunk, or bag. If multiple mycotoxins are present, these can compound the impacts on animals’ health and productivity.

Tip #3: Starch is an important component of crops like corn silage and even sorghum silage, however, proper kernel or berry processing is essential to ensure that the starch can be utilized by the animal and rumen microbes at feed out. Several tools can be utilized to help monitor the degree of kernel processing at harvest. Methods like tracking the amount of whole and cracked kernels in a 32 oz cup can help track in-field performance, while measuring the kernel processing score (KPS) in the lab helps hone in on optimal processing. The current recommendation for KPS is at least 70 with ideal levels closer to 75. Rock River Laboratory has also developed a new NIR model that can rapidly predict if samples are above or below the threshold of 70.

Don’t forget about sorghum! New berry processors have shown the ability to crack sorghum berries - making the starch much more available. Current estimates are that processing may increase starch disappearance at 7 hours to greater than 70+% after ensiling! However, similar to corn, letting the crop get too mature can decrease this starch availability. For producers looking to maximize rumen available starch content in sorghum, current recommendations from experts like Juan Piñeiro are to harvest at late soft dough to hard dough stage, and avoid letting the crop get to black layer stage. When monitoring berry processing, the berry processing score (BPS) can be utilized to track and ensure adequate processing is occurring. Current recommendation is a BPS of 50, assessed using the 2.36mm sieve.